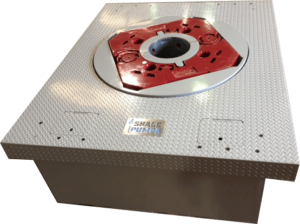

The rotary table is a rotating device that is typically used in making a hole with a drill process. It offers clockwise revolving energy to the drill cord. This is principally used to smooth the progress of the progression of drilling a borehole. The rotary speed of the machine is called rpm in short- the number of rotations executed per minute. In the construction industry, rotary tables are called as ‘turntables’. At Shale Pumps, we offer the quality of the construction equipment and if you are interested in knowing more about the functioning of this equipment, you can scroll down and check out:

Most of the rotary tables utilize chain–driven mechanisms of working. The major purpose and progress of the chain look like the rotation of a bicycle chain gathering. The chain needs regular lubrication in order to stay away from seizing and flaming. Most of the rotary tables have a rotary lock which is installed at the table which is to be moved in a permanent path. You can unlock it and free the equipment from its various limitations by allowing it to move in dual directions. This characteristic is frequently used by crews as an alternative of using the second pair of the tongs in order to make up or break up the pipes.

In the corner of the table is a brushing installed that is removable. It can be removed in the two different parts in order to allow the bigger items including the drill bits to cross the table. The large gap of the rotary table is known as a bowl and the slips are set within the bowl to clutch up the drill cord during associations and pipe trips the length of with the position where the drill string cross through the floor into the wellbore.

Hope the above mentioned information regarding the rotary tables gives you an overview of the points discussed above. If you have any further questions regarding the equipment, you can feel free to contact us at Shale Pumps. You can write back to us in the comment section below and we will get back to you.