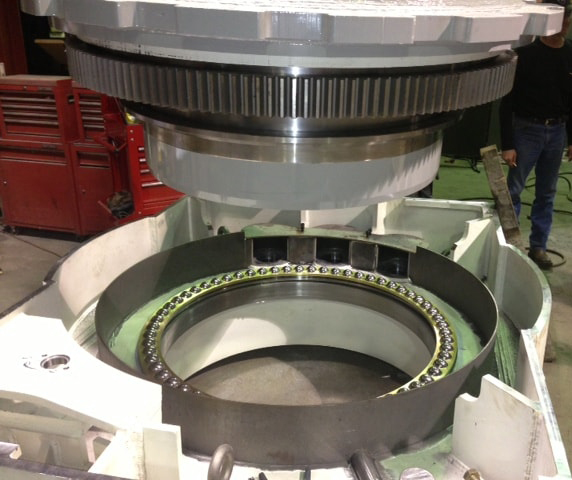

Fabrication

Synchronization and robust build are the two defining qualities of pumps in the Oil and Exploration sector. ShalePumps are trusted and acknowledged experts in this sector, specialists in this niche manufacturing domain. Our sheet metal fabrication services are executed in textbook fashion, with the tightest tolerances in the industry. It is not without reason that the pumps we make conform to the highest standards. Our sheet metal fabrication services are based on sound engineering principles and expertise.

There is no substitute for experience. The expertise of fitters and welders at ShalePumps is constantly updated and improved upon. Consequently, the state-of-the art equipment are handled better. Our sheet metal fabrication services rely on scientific methods to overcome undesirable fallouts, for instance, residual stress.

A combination of process capability and TQM shield the finished dimensions from going beyond tolerance values. With precision, quality and resilience as objectives, our sheet metal fabrication services surpass standards others aim to achieve. Manufacturing being inextricable from engineering, our fabrication relies a lot on advanced principles.

This is witnessed in the quality of what we put together. The welders and fitters in ShalePumps are living books of engineering. Weathered and seasoned, no doubt, but competent in a manner that reflects our very ethos.

At ShalePumps LLC, we know how to design and build pumps but that isn’t all that we’re good at. Our qualified welders and fitters have the experience and expertise to provide our customers with quality results that meet the highest standards in the industry and we are proud of it.