A rotary table is a rotating apparatus used mostly in drilling rigs to deliver a clockwise rotational force to a drill string. This makes it useful in enabling the process of creating a borehole. Rotary speed is also referred to as the rounds per minute (rpm), which pertains to the number of rotations that can occur in one minute. Rotary tables are sometimes called, ‘turntables’ in the oil and gas drilling industry. They are provided by reputable companies specializing in fracking and mud pumps, such as Shale Pumps, and it is advisable that you work with such equipment providers, so you can get the best value for your money in drilling equipment.

The rotary table would typically use a chain-driven mechanism, similar to the chain assembly you would find on a bicycle. This chain needs to be lubricated frequently to prevent burning and seizing. Rotary tables typically have a rotary lock, which is present to keep it moving in a fixed direction. However, it can be unlocked to prevent restrictions, so you can move the rotary table in either direction.

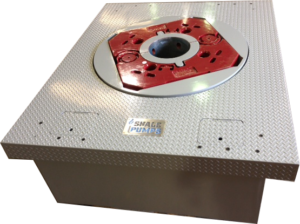

At the center of rotary tables, you can find the bushings that can be removed in separate pieces, so bigger items, like drill bits, can pass through them. A large gap in the heart of the table is known as the ‘bowl’ due to its appearance and shape. Slips are applied in the bowl to keep the drill string in place during pipe trips and connections as the drill string goes through the wellbore. Bushings link to kelly bushings to initiate the spin to start drilling.

Modern drilling rigs may not have a rotary table anymore, as it has been replaced with high-end top-drive technology, in which the drill string turns due to the mechanism found on top of a string. The top drive is connected to the blocks, eliminating the need for a swivel, as all the important actions occur at the top drive. Despite this, kelly bushings and the kelly bar are still used.